Monthly Archives: February 2018

-

Continue Reading »

The use of barcode scanner imagers (CCD, Linera Imagers) has been increasing due to the adoption of 2D symbols in many warehousing and Point of Sale ("POS") applications. Laser scanners are generally more accurate and scan barcodes with higher speeds in most applications.

The best barcode scanning solution for you will be dictated by requirements of an application, the enviroment and your budget.

Lining up the barcode: Omnidirectional vs CCD, Laser and Linear Imager

- CCD, Laser and Linear Imager barcode scanners are single line, hand-held or hands free, barcode scanners and you must line up the barcode to scan it.

- Omnidirectional is a form of Laser scanning specifically for hands free scanning, and projects multiple lines (or lasers) so that you can easily and quickly swipe a barcode past without even having to line up the barcode. This scanning techonolgy is popular in high traffic areas such as convenince stores, fuel stations, and liquor stores.

Laser vs CCD vs Linear Imager vs Omnidirectional

Laser

Disperses a laser dot into a thin solid line and in turn projects it onto a barcode. The laser beam repeatedly moves from left and right, hence the scanner has moving parts.

Advantage: They can scan in direct sunlight (in most instances), and project a thin, very precise laser beam onto the barcode. Using laser scanners allows for the reading of wide and distant bar code labels.

Disadvantage: Struggles to scan small barcodes or high resolution barcodes (Not as good ion as Linear Imager scanners), and has moving parts that can break.

CCD (Charged Coupled Device)

Light detectors aligned in a single row eluminates the barcode, and an actual lens in the scanner reduces the full barcode image onto the imaging sensor. CCD barcode scanner technology is based on camera imaging technology.

Advantage: This method is great for capturing very high resolution details along with widened color space. It can also scan folded lines, and has no moving parts.

Disadvantage: Has a close scanning range, and is generally not used for medium to long distance scanning.

Linear Imager

Based on the same technology as CCD scanners (imager), but has a longer range, comparible to Laser barcode scanners.

Advantage: Able to scan smaller barcodes than lasers scanners. Genreally more rugged than Laser scanners because they have no moving parts.

Disadvantage: Usually can't scan in direct sunlight

Omnidirectional

The next level up from normal Laser barcode scanners, it projects 20 or more lines (instead of a single line), so that you don't have to line up the barcode as you swipe it fast. It's ideal for fast hands free scanning.

Advantage: No need to line up the barcode when swiped fast. Ideal for hands free or presentation scanning.

So which one works for me?

For short range scanning: CCD scanners are a good choice if price is an issue and occasionally scanning barcodes.

For long range scanning: Laser scanners are geenrally the best choice, with some rugged scanners able to scan up to 100 meters long.

Laser vs Linear Imager: For the vast majority of applications ir won't make a diffrence choosing between a Linear Imager or a Laser, unless you need to scan really small barcodes (use Linear), or you have to scan in sunlight (use Laser).

Hands free scanning: Omnidirectional is almost always better than Laser or Linear Imager because it has multiple beams negating the need to line up the barcode onto a single beam.

-

Continue Reading »

This comparison of the Zebra series of 4 inch desktop label printers includes the GC420, GK420 and GX420 printers

These are alll desktop printers suited for light to medium volume barcode and label printing, and include 2 inch and 4 inch printers. 2 inch printers are used mostly for printing barcodes up to 54mm wide, and 4 inch printers are used mostly for printing shipping labels and larger barcode labels. All the models are available in either direct thermal technology (Model "D"), or direct thermal and thermal transfer techonology (Model "T"), and come in either 203 dpi or 300 dpi print resolution.

The main differences between these three lines of printers are their print speed and interface options. As the price increases it will provide more interface options, additional options such as auto cutters, and better print speeds.

Here is a summary of the benefits and differences of these label printers:

Zebra GC420 (Replaced the Zebra TLP2844)A simple, entry-level desktop label printer in this series, and is the most competitively priced.

Delivers quality, durability and reliable performance for low to medium volume printing applications.

Print speed: 4 inches per second .

Interface options: USB, Serial, Parallel.

Thermal Direct (GC420d) and Thermal Transfer (CG420T) models are available.Zebra GK420 (Replaced the Zebra LP2844)

A solid mid-range printer in this series, reliably prints clear labels and barcodes.

Has faster print speeds and network manageability for medium to large organisations.

Fast print speed: 5 inches per second.

Interface options: Ethernet, USB, Serial, Parallel.

203 dpi, Thermal Direct (GK420d) and Thermal Transfer (GK420t) models available.

Additional options include: ZebraNet® 10/100 Print Server & Asian and international font kitsZebra GX420 and GX430

The highest-performance printer in this series, the GX420 is flexible and and efficient.

Provides the fastest print speeds, and packed with extra features and options.

Print speed: 5 inches (GX420) and 6 inches (GX430) per second.

Interface options: WiFi 802.11b/g, Bluetooth, Ethernet, USB, Serial, Parallel.

203 dpi (GX420) or 300 dpi (GX430)

Thermal Direct (GX420d or GX430d) and Thermal Transfer (GX420t or GX430t) models available.

Additional options include: LCD screen, Adjustable media sensor for black line media, Auto Cutter -

Continue Reading »

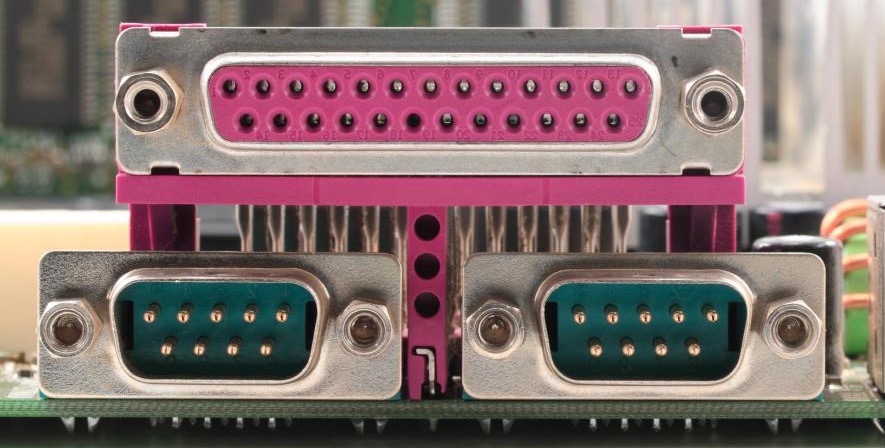

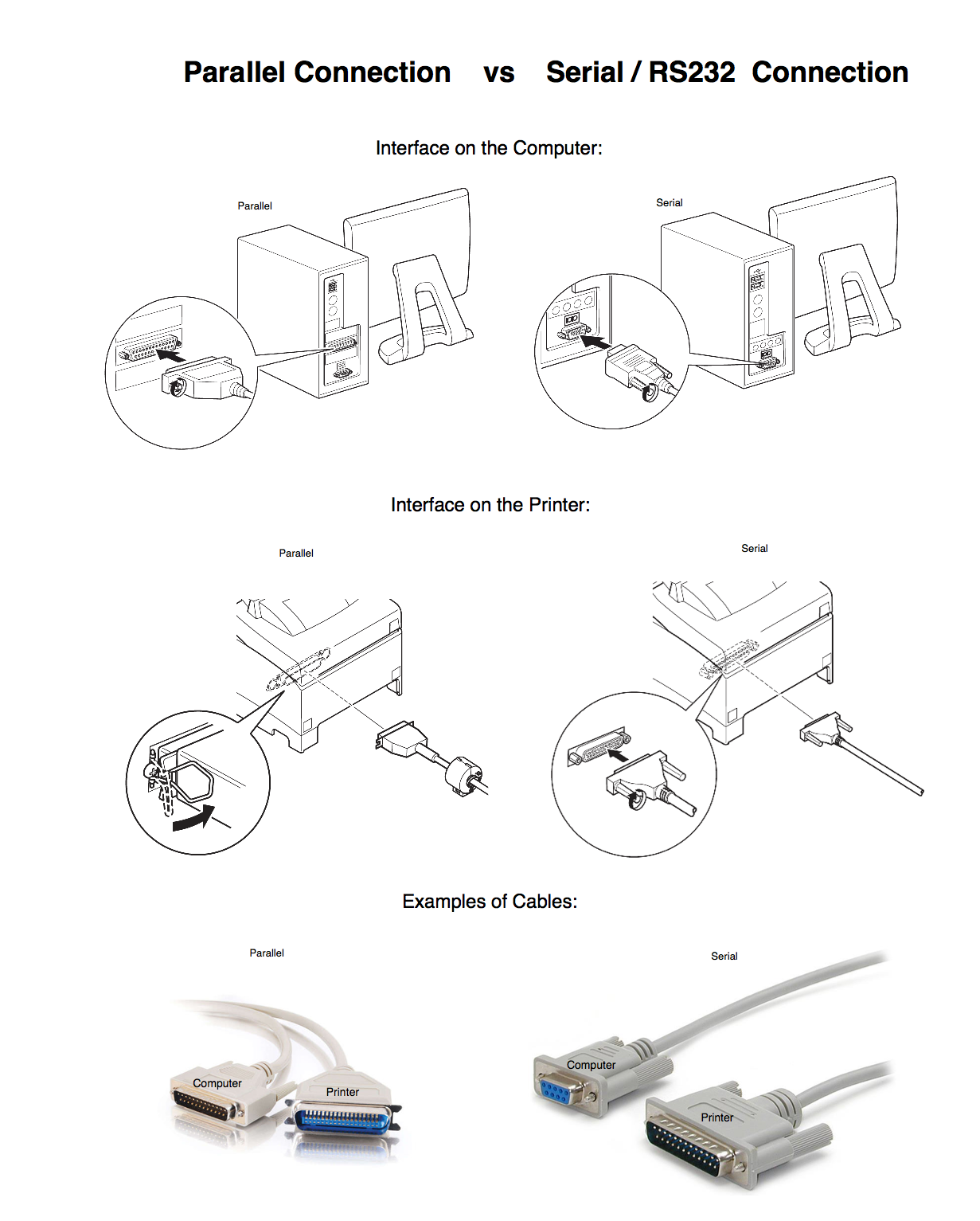

Interface on the Computer:

The parallel port found on computers is for connecting peripherals, where many bits of data are sent at once, in parallel communication, and requires multiple data lines in their cables and are also larger than the modern serial ports. Modern computers tend to be manufactured without serial ports, and require serial-to-USB converters to allow compatibility with Serial / RS-232 serial devices.

The serial port is a serial communication interface, that sends bits of data, one at a time, requiring one data line and are smaller than the parallel ports. Suprisingly and interestingly, interfaces such as Ethernet, FireWire, and USB sends data as a serial stream. Serial port identifies hardware as compliant to the RS-232 standard, intended to interface with a modem or with a similar communication device.

Serial ports are still used in applications like point of sale systems, scientific instruments, industrial automation systems, and some industrial and consumer products. Server computers may use a serial port as a control console for diagnostics. Network equipment (such as routers and switches) often use serial console for configuration. Serial ports are used in these areas as they are simple, cheap and their console functions are highly standardized and widespread. A serial port requires very little supporting software from the host system.

Interface on the Printer:

Pre-2000, desktop printers had one of two interfaces: serial and parallel. The type of interface decreed how fast the cable between printer and computer carried data.

A parallel interface was faster, using a thicker, more complex cable.

The serial printers were cheaper but slower though it allowed for larger distances between the printer and computer.

Today, the parallel port interface is practically non-existent because of the popular Universal Serial Bus (USB) devices, along with network printing using Ethernet and Wi-Fi connected printers.

Examples of Cables:

The parallel interface needs many wires to carry 8 or more bits of a byte at a time, adding to the cable's complexity and cost.

Cables for serial printers use multi-wire cables fitted with nine or 25-pin "D" type miniature connectors, one pair of wires for sending, one for receiving, an electrical ground and data signalling wires. It uses two wires to carry data each way, sending data one bit at a time. A printed document becomes a stream of ones and zeros in single file.

Sources:

https://en.wikipedia.org/wiki/Parallel_port

https://en.wikipedia.org/wiki/Serial_port

http://smallbusiness.chron.com/serial-printer-57640.html

https://www.techwalla.com/articles/difference-parallel-port-serial-port